Understanding the Label Release Liner: A Key Component in Pressure-Sensitive Labeling

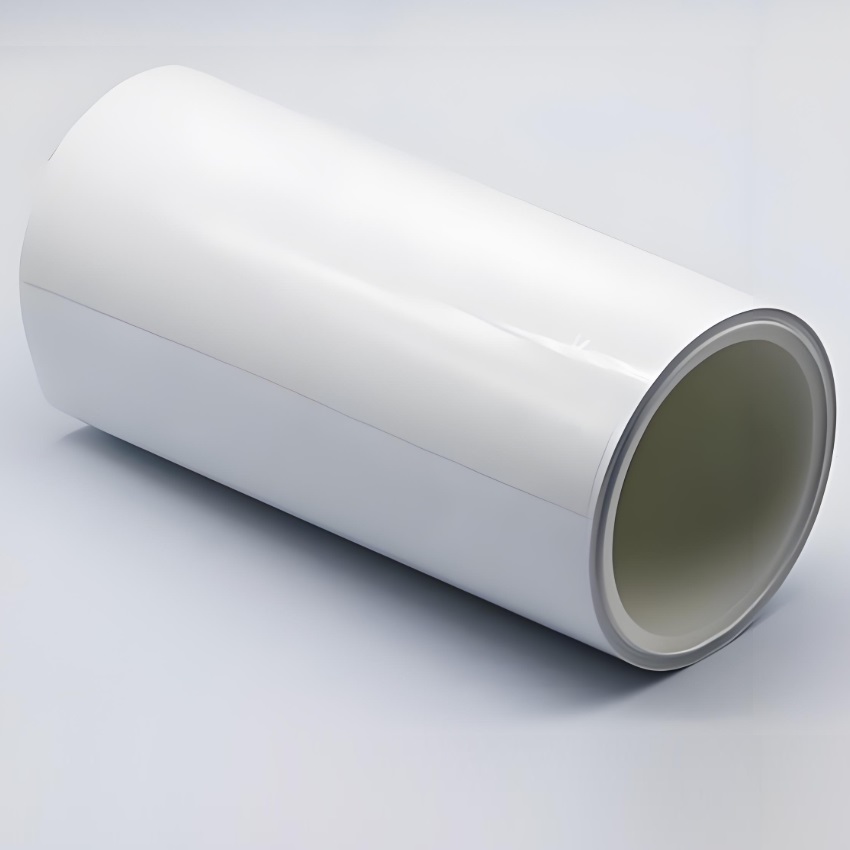

Labels play a vital role in product packaging - not only for aesthetics and branding, but also for regulatory compliance and product identification - and the Label Release Liner is an often-overlooked but critical part of this process. Although it may seem like an insignificant component, it is critical to ensuring that labels work properly and are applied efficiently.

The main functions of release liners

- Support and protection: Release films provide a stable substrate for labels during printing, die-cutting and shipping, ensuring that labels maintain their shape and adhesive integrity.

- Easy to apply: smooth release is essential for fast and accurate labeling, whether manual or automated.

- Machine compatibility: In high-speed labeling systems, consistent release force is critical to maintaining operational efficiency and avoiding jams or misfeeds.

Common Materials

Label Release Liners are typically made from the following materials:

- Paper (e.g., Grazian or Super Calendered Kraft): cost-effective and environmentally friendly.

- Films (e.g. PET or polypropylene): High strength, transparency and moisture resistance, ideal for high performance or clear labels.

Applications in a variety of industries

Label Release Liner is used in a wide variety of applications:

- Food & Beverage: for eye-catching product labeling.

- Pharmaceuticals: for tamper-evident and compliance labeling.

- Logistics: for barcode and shipping labels.

- Consumer goods: for branding and instructions for use.

Sustainability Challenges and Innovations

A major problem with release liners is waste - as they are often discarded after use. For this reason, manufacturers are developing release-film-free labeling technologies and recyclable or biodegradable release films to reduce their environmental impact.

Although Label Release Liners are often unnoticed by end users, they are the cornerstone of the labeling process. They play an important role in supporting, protecting and ensuring the smooth application of pressure-sensitive labels, making them an integral part of a wide range of industries. As the need for sustainability grows, innovations in backing materials and recyclability will continue to shape the future of labeling solutions.